The control plan stored in the plc is called – In the realm of programmable logic controllers (PLCs), the control plan takes center stage, orchestrating efficient operations and ensuring seamless performance. Delve into this comprehensive guide to unravel the intricacies of the control plan stored within the PLC, exploring its significance, storage methods, and best practices.

As the cornerstone of PLC operation, the control plan serves as a blueprint, outlining the sequence of actions and decision-making criteria that govern the PLC’s behavior. Its importance lies in optimizing performance, minimizing downtime, and ensuring the reliability of the entire system.

Control Plan in PLC

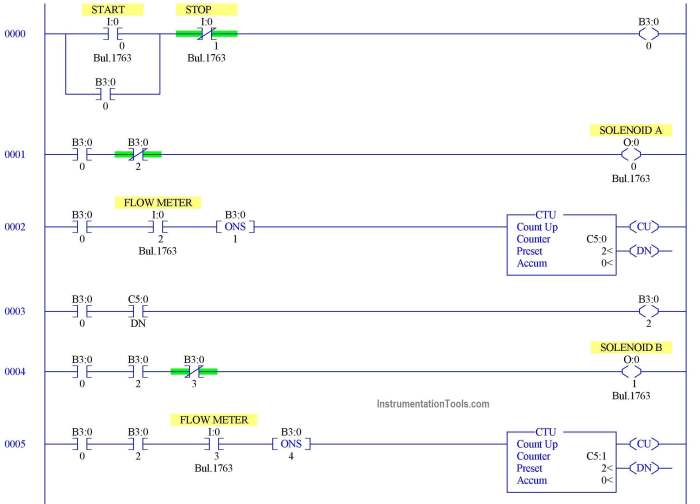

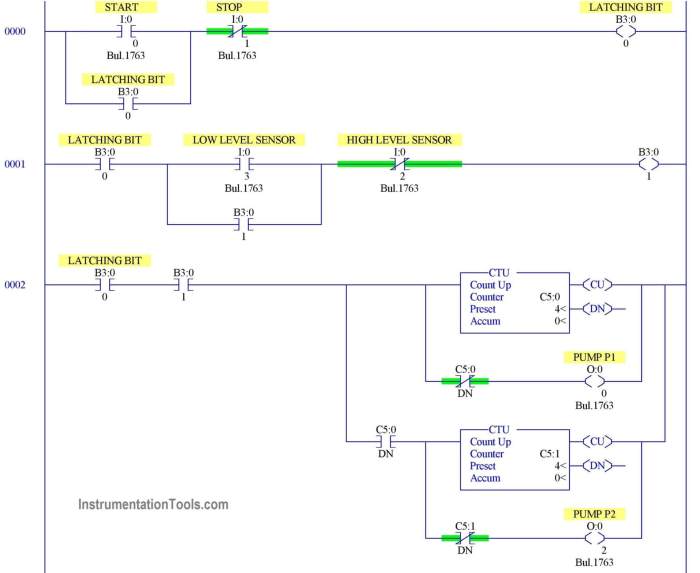

A control plan in a PLC (Programmable Logic Controller) defines the logic and sequence of operations that the PLC will execute to control a specific process or system. It serves as a blueprint for the PLC’s behavior and ensures efficient and reliable operation.

Components typically included in a control plan include:

- Input variables (e.g., sensor readings, operator commands)

- Output variables (e.g., actuator control signals)

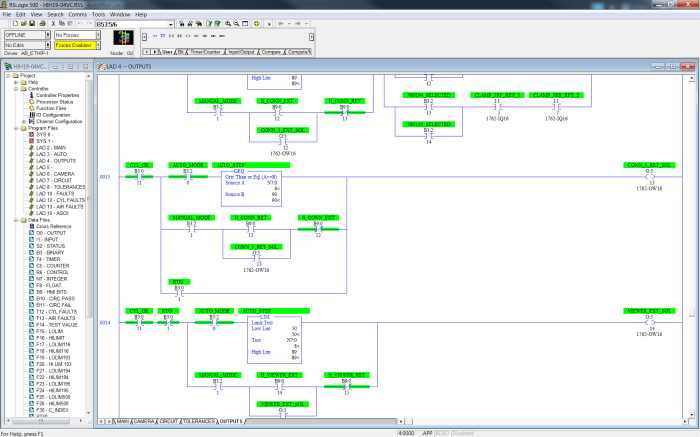

- Program logic (e.g., ladder diagrams, function blocks)

- Timing and sequencing parameters

- Fault detection and handling routines

PLC Storage of Control Plan

The control plan is stored in the PLC’s memory, which can be either volatile or non-volatile. Volatile memory, such as RAM, loses its data when power is removed, while non-volatile memory, such as EEPROM, retains data even when power is off.

There are two main methods for PLC control plan storage:

- Embedded storage:The control plan is stored directly in the PLC’s firmware or memory module.

- External storage:The control plan is stored on an external device, such as a memory card or USB drive, and loaded into the PLC’s memory when needed.

Embedded storage is more secure and reliable, but external storage allows for easier updates and changes to the control plan.

Types of Control Plans in PLC: The Control Plan Stored In The Plc Is Called

There are several types of control plans used in PLCs, each with its own applications and limitations:

- Sequential control:Executes a series of steps in a predefined order.

- State-based control:Transitions between different states based on input conditions.

- Event-driven control:Responds to specific events or triggers.

- PID control:Regulates a process variable by comparing it to a setpoint.

- Motion control:Controls the movement of motors or other actuators.

Benefits of Using Control Plans in PLC

Control plans offer several benefits in PLC systems:

- Improved performance and reliability:Ensures that the PLC operates as intended and responds to changes efficiently.

- Reduced maintenance and troubleshooting:Provides a structured approach for identifying and resolving issues.

- Enhanced safety:Includes fault detection and handling routines to prevent hazardous situations.

- Increased flexibility:Allows for easy modifications and updates to the control logic.

- Improved documentation:Provides a clear and concise record of the PLC’s operation.

Best Practices for Control Plan Implementation

Effective implementation of control plans in PLC systems requires following best practices:

- Plan and design:Carefully define the control requirements and develop a clear and concise control plan.

- Testing and validation:Thoroughly test and validate the control plan before implementation.

- Documentation:Create comprehensive documentation that describes the control plan and its implementation.

- Training:Provide training to operators and maintenance personnel on the control plan and its operation.

- Regular reviews and updates:Regularly review and update the control plan to ensure it remains effective.

Troubleshooting Control Plan Issues

Common issues that can occur with control plans in PLCs include:

- Logic errors:Incorrect or missing logic can cause the PLC to behave unexpectedly.

- Hardware faults:Faulty sensors or actuators can lead to inaccurate input or output data.

- Communication problems:Issues with communication networks can prevent the PLC from receiving or sending data.

- Environmental factors:Extreme temperatures or vibrations can affect the PLC’s operation.

Troubleshooting control plan issues involves:

- Identifying the symptoms:Observe the PLC’s behavior and identify any deviations from expected operation.

- Analyzing the control plan:Review the control plan and identify any potential errors or inconsistencies.

- Testing and verifying:Make changes to the control plan and test the PLC’s operation to verify the issue is resolved.

- Documenting the solution:Record the steps taken to troubleshoot and resolve the issue.

Common Queries

What is the purpose of a control plan in a PLC?

A control plan provides the PLC with a structured set of instructions that define the desired behavior and response to various inputs and conditions, ensuring efficient and reliable operation.

How is a control plan stored in a PLC?

Control plans can be stored in a PLC’s memory using various methods, such as ladder logic, function blocks, or structured text, depending on the PLC’s capabilities and the complexity of the control plan.

What are the benefits of using a control plan in a PLC?

Control plans enhance PLC performance by providing a clear and organized structure for programming, reducing errors, simplifying troubleshooting, and facilitating maintenance.

What are some best practices for implementing a control plan in a PLC?

Best practices include defining clear objectives, documenting the control plan thoroughly, testing and validating the plan before implementation, and conducting regular reviews and updates to ensure its effectiveness.

How can I troubleshoot issues related to a control plan in a PLC?

Troubleshooting involves identifying potential errors in the control plan, examining the PLC’s status and diagnostic information, and making necessary adjustments or repairs to restore proper operation.